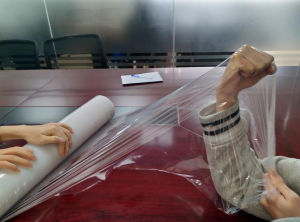

How Stretch Wrap Film Innovates Technology For Enterprise Cost Reduction and Efficiency Improvement

In the ultra-competitive (and highly globalized) business world we have today, many businesses are on the lookout for ways to streamline their activities and lower operating expenses, whilst maintaining standards of quality/efficiency. The stretch wrap film technology, in particular, had seen some substantial developments. Newer products of stretch wrap film pack processes as more efficiently and with greater cost efficiency for manufacturers, wholesalers and other businesses.

Saving Time And Money With Advanced Film Technologies

The most significant advancement in stretch wrap film technology is the use of nano-layered films. The films contain extremely thin layers of polymers that improve tensile strength and tear resistance while minimising overall film thickness; this allows the manufacturer to use less material to achieve the same level of load stability, which reduces both material costs and waste.

Another important innovation are the pre-stretched films. Such films are stretched through the manufacturing process, making it possible to apply them using less force, while also offering higher levels of load retention. This way, not only is the physical effort of manual wrap reduced, but also the consistency of wrap and the amount of material used。

Intelligent Solutions for Film Application

Apart from improvements in the film materials, the installation process has been transformed through the incorporation of smart systems. Today, stretch wrap machines are equipped with advanced automation technologies that accurately locate and apply stretch film to pallet loads.1 Robopac USA’s patented Cube Technology, for example, can ensure uptime with minimal operator interference and significantly reduce operator error while improving coverage.

Another breakthrough is smart film tension control These machines utilize sensors and smart controls to constantly monitor and adapt the film’s tension during the wrapping process. This means the film is able to be appropriately stretched for optimal containment without the risk of ripping.

Savings and Ecological Balance

These developments in high-performance film materials paired with intelligent application systems have resulted in significant savings for companies. Movies are becoming more economical as manufacturers such as Robopac USA have proven that by optimizing pre- stretch, film placement, and containment force film savings of 30 to 55 percent can be achieved while also slashing films used for sustainability objectives and waste packaging materials.

Tailor-Made Solutions for Various Needs

This has led to manufacturers offering tailor-made stretch film solutions catering to the needs across the industries; industries demanding high load stability use cling films, while the electronics packaging sector opts for anti-static films.

Manufacturers and Wholesalers Responsibilities

These innovative stretch wrap film solutions drive their demand through the work of manufacturers and wholesalers. This in turn helps businesses in maximizing the best aspects of packaging processes while reducing costs with their ‘just right’ techniques due to higher application of advanced technologies while providing various customized products (Robopac USA, Zenith Stretch Film).

Conclusion

Stretch Wrap film is nothing new and has been around for some decades for the purpose of packaging goods, the only difference is its ever-evolving technological innovations in the domain. Due to the first improvements in film materials itself, smart application systems, and tailored solutions, industries offer a prominent an important way for manufacturers and wholesalers to assist enterprises in delivering substantial cost savings and reassurance of supply chain excellence globally; the suppliers will need to be on top of the game or be left behind as they say, “innovation is the name of the game.”

Post time: May-26-2025