Advanced Printing Technology in Adhesive Tape Manufacturing: A Leap Forward

In the dynamic world of industrial manufacturing, the evolution of adhesive tape production has been significantly propelled by advancements in printing technology. This progress is not just about enhancing the visual appeal of tapes but also about improving functionality, durability, and efficiency. Today, we delve into the transformative role of advanced printing technology in adhesive tape manufacturing and how it is reshaping the industry.

The Evolution of Adhesive Tape Manufacturing

Adhesive tape manufacturing is a complex, multi-step process that involves transforming raw materials into finished products used across various industries. The traditional process includes adhesive preparation, substrate preparation, coating, drying, slitting, and packaging. Each step is critical in determining the final properties and performance of the tape. However, with the advent of advanced printing technology, this process has become more efficient, precise, and versatile.

The Impact of Advanced Printing Technology

Advanced printing technology has revolutionized the way adhesive tapes are manufactured and used. Here are some key areas where this technology has made a significant impact:

1. Enhanced Precision and Customization

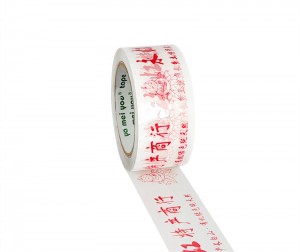

One of the most notable advancements is the ability to print highly detailed and customized designs on adhesive tapes. This is achieved through state-of-the-art printing equipment that allows for precise ink deposition, ensuring high-resolution prints Custom-printed adhesive tapes are now used for branding, labeling, and even functional purposes such as electrical insulation and thermal management.

2. Increased Durability and Performance

Modern printing techniques enable the integration of durable inks and coatings that enhance the tape’s resistance to environmental factors such as UV radiation, chemicals, and abrasion. This means that printed adhesive tapes can maintain their integrity and appearance over extended periods, even in harsh conditions.

3. Efficiency in Production

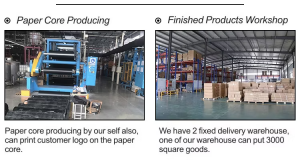

Advanced printing technology also contributes to increased production efficiency. High-speed printing presses and automated processes reduce production time and costs, making it feasible to produce large volumes of custom tapes quickly. This is particularly beneficial for industries that require just-in-time manufacturing and short lead times.

4. Innovative Applications

The integration of smart materials and nanotechnology has opened up new possibilities for adhesive tapes. For instance, tapes can now incorporate temperature sensors, moisture detectors, and even electrical conductivity, expanding their applications in electronics, automotive, and construction industries.

The Role of Printing Adhesive Tape Manufacturers

Printing adhesive tape manufacturers play a pivotal role in driving these innovations. Companies like Design Tape specialize in high-quality custom-printed adhesive tapes and labels, offering tailored solutions with competitive pricing and premium quality. These manufacturers invest heavily in research and development to stay ahead of the curve and provide cutting-edge products to their clients.

Key Players in the Industry

Several companies have emerged as leaders in the field of advanced printing technology for adhesive tapes:

-

Matrix Technology focuses on maximizing offset printing efficiency with high-performance adhesive tapes. Their products are designed to improve workflow, enhance print accuracy, and reduce maintenance challenges.

-

NADCO Tapes & Labels is a seasoned leader in custom manufacturing, offering services such as printing, converting, and die-cutting. They have completed over 10,000 projects, showcasing their expertise in handling complex, customized requests.

-

ATPrinters is another notable player, known for its state-of-the-art equipment designed solely for

-

manufacturinghigh-quality printed tape. They offer low minimums and short lead times, making it easier for distributors to service their accounts and gain new business.

The Future of Adhesive Tape Manufacturing

As technology continues to advance, the future of adhesive tape manufacturing looks promising. Innovations such as additive manufacturing (3D printing) are already transforming the production of industrial tapes, allowing for precise customization and on-demand production. Additionally, the development of multifunctional tapes that combine adhesive, sealing, and insulation properties is set to revolutionize various industries.

Conclusion

Advanced printing technology has significantly enhanced the capabilities of adhesive tape manufacturing. From increased precision and customization to improved durability and efficiency, these advancements are transforming the way adhesive tapes are produced and used. Printing adhesive tape manufacturers are at the forefront of this revolution, driving innovation and delivering high-quality products that meet the evolving needs of modern industries.

As we look to the future, the continued integration of advanced printing technology promises to bring even more exciting developments to adhesive tape manufacturing. Whether it’s through smarter materials, more efficient processes, or innovative applications, the industry is poised to make a significant impact across various sectors.

For businesses seeking to leverage these advancements, partnering with leading printing adhesive tape manufacturers is crucial. Companies like Design Tape, Matrix Technology, and ATPrinters offer a wealth of expertise and cutting-edge solutions that can elevate your adhesive tape needs to new heights. Embrace the future of adhesive tape manufacturing and discover the endless possibilities it holds.

Post time: May-13-2025